Made some trial panels from plastic. I’ll use these to lay out the panel and make sure everything fits before I start cutting metal. I’f I do this properly and everything works out, I should be able to use these as templates to lay out the actual metal panels.

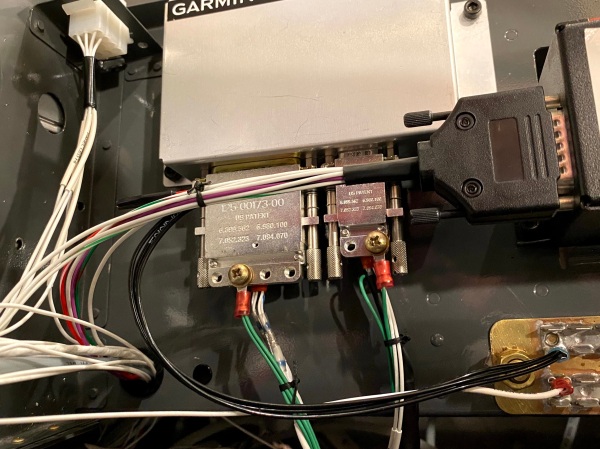

Temporarily mounted the GAD27 (ARINC), GAD29 (electrical device controller), and GEA 24 engine indication system. I mounted the GEA 24 directly to the sub panel. I made a stand-off mount for the GAD 27 using some aluminum sheet and some aluminum tubing. This let me “stack” the two boxes fore and aft. This was the same approach that Jared took in his plane. So I can’t claim credit. I also mounted the TCW integrated backup battery system. I fit the boxes, drilled the sub panel, and attached the boxes with temporary hardware I had lying around. I’ll get the proper hardware this week.

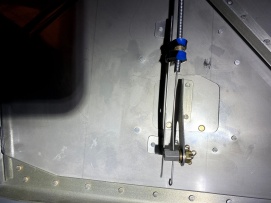

I fabricate a doubler to mount the WaaS GPS antenna. I cut a piece of aluminum to sive, laid out the holes for the antenna and rivets. I match drilled the empennage top skin to the doubler. I dimpled the doubler, riveted nut plates to it, and primed with SEM rattle can. I dimpled the top skin with the pop rivet dimple dies. I riveted the doubler to the inside of the skin and screwed the antenna in place with the supplied hardware.

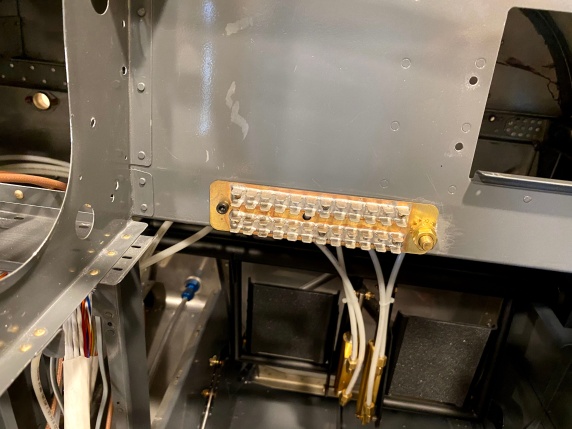

Started fitting the radio stack. I used a digital level and shimmed up the front of the radios so that the were perpendicular to the panel. Determined that I need to enlarge the center opening in the sub panel in order to accommodate the radios without blocking the canopy release. Even then, everything barely fits.

I picked up a vibratory cutter and a flush cutting blade. I’ll use this to cut the sub panel tomorrow.

| Today’s Time (hours): |

6.0 |

| Options and Miscellanea Time (hours): |

7.0 |

| Total Time (hours): |

682.5 |