In case you haven’t noticed, I’ve settled into a strategy for most sections of the build… First I pick, inspect, and peel all the parts for the section. The I take a first pass through the instructions and perform all of the steps that require cutting, grinding, bending, etc. Then I deburr, scuff, and dimple all the parts. Then I prime everything. Finally I assemble and rivet everything. I’ve found this approach is much quicker then going step by step in the order of the instructions. I can set up the shop and tools for each operation and reorganize after each operation. I kind of get into a groove with each of the operations and avoid frequent tool changes. I also only need to set up for paint, which is a major operation, once per section.

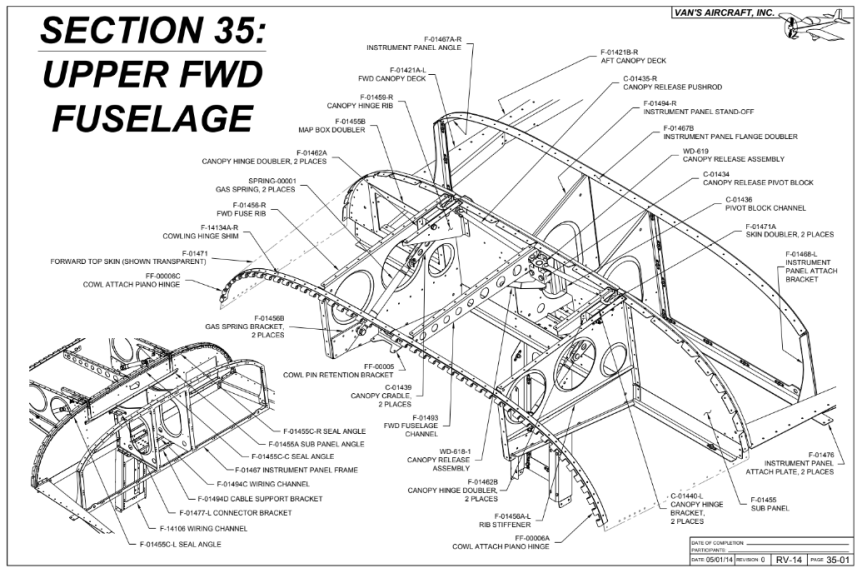

Today I was focused on fabrication steps… I started with the upper longerons. I cut and trimmed according to the plans. The fabricated a couple of clamping blocks that allowed me to secure each longeron in the bench vise and clamp a lever to the end in order to bend a 10 degree twist into them. Finally I clamped and clecoed the upper engine mount brackets to the forward end of the longerons and match drilled them.

Drilled and cut the lower longerons and match drilled them to the lower engine mount brackets and longeron doublers.

Fabricated the hinges that will attach the cowling to the firewall.

Separated a whole bunch of parts. Unfortunately my bandsaw blade gave up the ghost early on and I didn’t have a spare. So I used the snips for the thinner aluminum and the Dremel with a cutoff wheel for the thicker parts. A little bit slower but not too bad.

I managed to lose a part somehow. I turned the shop upside down and couldn’t find the F-01422 Fuselage Side Ribs. I checked it off on the inventory. No idea what happened to it. Ordered a new one from Van’s.

| Today’s Time (hours): |

5.0 |

| Fuselage Time (hours): |

80.0 |

| Total Time (hours): |

534.5 |