I used the edge roller to break the edge of the top and side skins where they meet the rear window. I final drilled the skins #27 and dimpled the holes for #6 screws. The squeezer wouldn’t fit into the space between the top skin and the roll bar brace. After a fair amount of ass-scratching I tried using a #6 screw and a K1000-06 nut plate to press the dimple into the center hole. It worked well.

I decided to wait until later to actually install the window. This will enable better access to the fuselage and keep me from beating up the window while I’m working on the rest of the stuff. But everything’s done and all I have to do is add some sealant and screw it in. For sealant I’ve decided to try Lexel. It’s a clear solvent based sealant that is safe for acrylic. Other builders have reported good success with it.

I separated, deburred, and painted the stiffener angles. I’ll rivet these in place as soon as the paint dries.

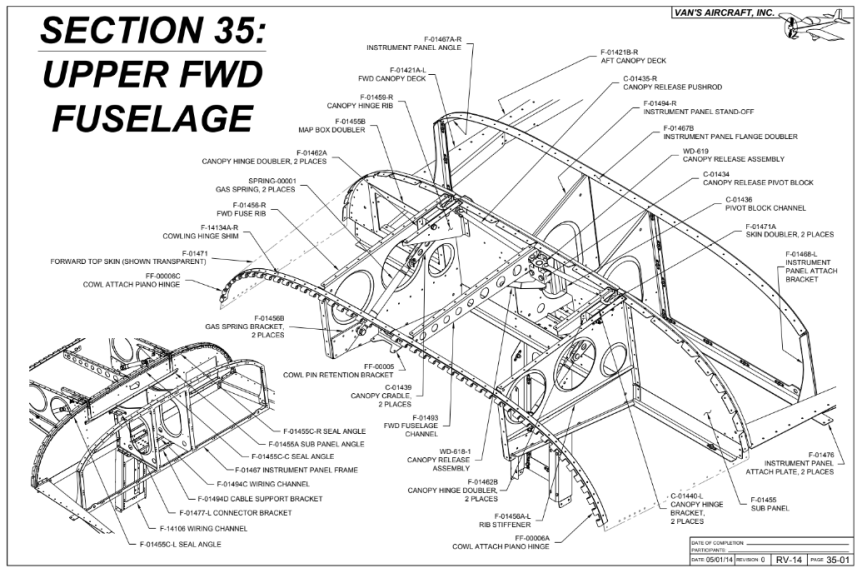

I picked and inspected all of the parts for the rest of the canopy.

I peeled all of the parts for the canopy latch mechanism. I separated the peices that needed parting. I deburred and scuffer all the parts. Then painted everything to match the interior.

I test fit the canopy latch pins in the bushings that I installed in the roll bar. I realized that I neglected to mask of the bushings when I painted the roll bar and got some paint in there. I wrapped some sand paper around a brass drift and used it to clear the paint. Everything fits fine now.

| Today’s Time (hours): |

4.0 |

| Finish Kit (hours): |

18.0 |

| Total Time (hours): |

748.0 |