Another busy week at work. Didn’t even have a chance to post last weekend’s build sesh. So here it is a week late.

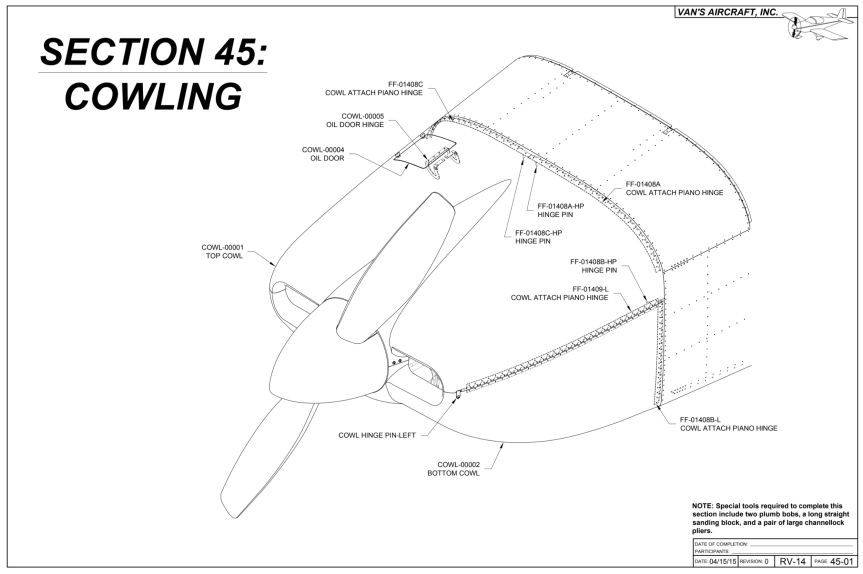

Fabricated and installed the cowling hinges

Trimmed the top and bottom cowling with a cut-off wheel in the Dremel and some course sandpaper on a long sanding block. Cut out the landing gear hole and the oil door.

Clamped the cowl halves together and fit, trimmed and sanded the spinner and air inlet areas. This took several iterations to fit properly.

Had to do a couple of iterations of trimming the aft edge of the top cowling to get it to fit in place. Marked the rivet locations on the cowling and drilled them. Then match drilled those holes to the cowling hinges.

Several iterations of trimming and sanding the bottom cowling aft edge, then the top edges. Marked the rivet locations and drilled them. The match drilled to the cowl hinges.

Clamped the hinges that join the top and bottom cowling in place. Layed out the rivet line and match drilled the bottom cowling to the hinges. Located and cut out the notches in the top cowling for the tabs that secures the hinge pins.

| Today’s Time (hours): | 12.0 |

| Finish kit (hours): | 253.0 |

| Total Time (hours): | 987.0 |