I was using the squeezer to do some dimpling and riveting. About halfway through it started leaking air from the valve. I disassembled the valve and found that the o-ring that prevents the poppet from-over extending had sheared in two. I called Cleaveland Tool and they were more than happy to ship a new o-ring at no charge. Nice folks over there. In the meantime I’ll be using the DRDT-2 and C-frame dimpling duties and shooting all the rivets with the gun.

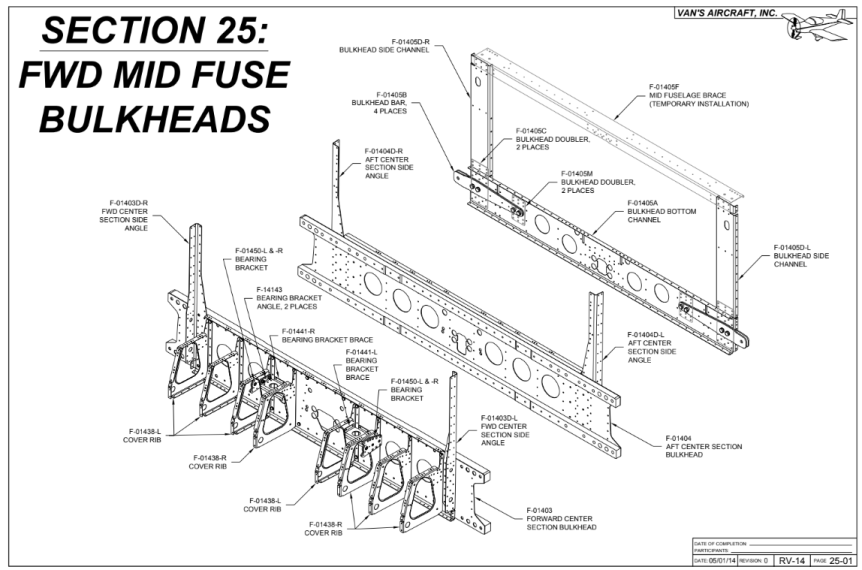

I assembled the bulkhead bars. Unfortunately I screwed up one of them and had to order a new part from Van’s. Here’s the good one…

I moved on the the aft center section bulkhead. I machine countersunk all the holes then riveted the nut plates in place. Then I riveted the side angles to the bulkhead.

I countersunk and riveted the bearing brackets.

I dimpled the cover ribs and riveted the nut plates in place. I riveted the bearing brackets to the ribs as well.

Machine countersunk the bearing bracket braces and riveted on the attach angles.

Moved on to the forward center section bulkhead. I machine countersunk the holes on the flanges and riveted on the nut plates. Then riveted and bolted the side angles in place.

| Today’s Time (hours): | 5.0 |

| Fuselage Time (hours): | 11.0 |

| Total Time (hours): | 465.5 |