After 20+ months of building, RV-14A, N3318S took flight for the first time today. I can’t put into words how gratifying it was to leave the earth in a machine that I built. Special thanks to Jared Solomon for making the first flight with me and for all the help along the way. Thanks also to Wesley Greer and Craig Garella for coming out today. The airplane flew amazingly well. No major squawks. Thanks to all the good folks at Van’s Aircraft who designed a wonderfully capable airplane in a well engineered kit. Can’t wait until the next flight!

Month: August 2020

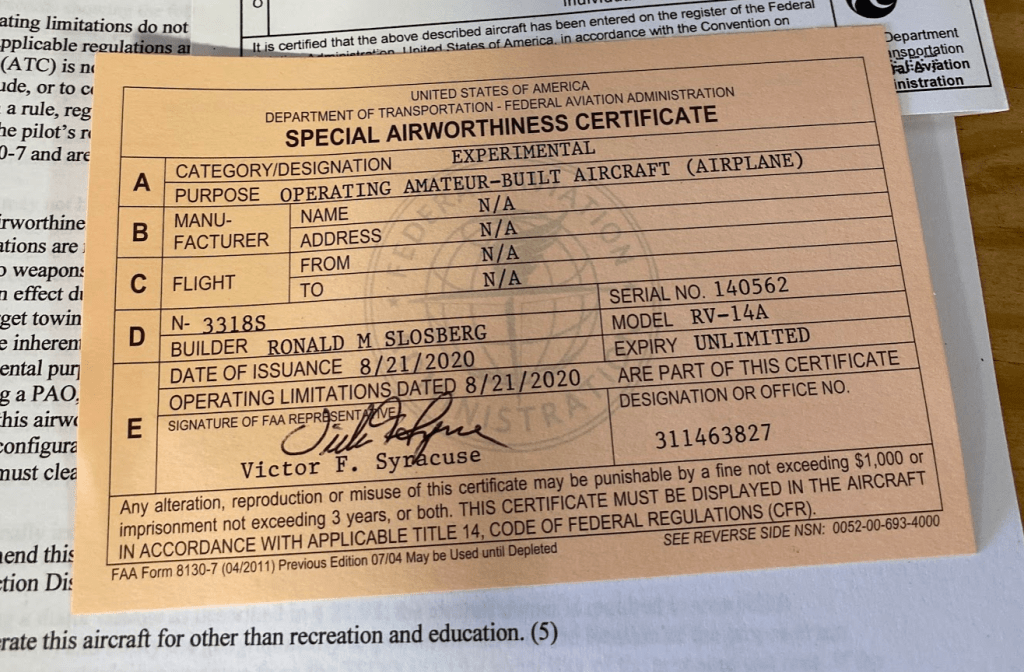

Moved to the airport, put the wings on, buttoned everything up, and got an Airworthiness Certificate!

I secured a shared hangar space at McCollum Field (KRYY).

I made cradles from heavy duty moving boxes that I bought from HD. This was cheap, quick and actually worked really well. Rented a U-Haul and packed everything up along with the wings and all of the tools to complete the project at the airport. Remy was a huge help getting everything moved.

Hired United Towing from Alpharetta to move the fuselage to the airport. They did a terrific job. I’ll be honest though… Watching my plane go down the road on the back of a flatbed was one of the most anxious experiences of my life.

Remy and I attached the stabilizers, ruder, and elevators. Then Jared and Wes showed up and we got the wings attached. Very exciting Day!

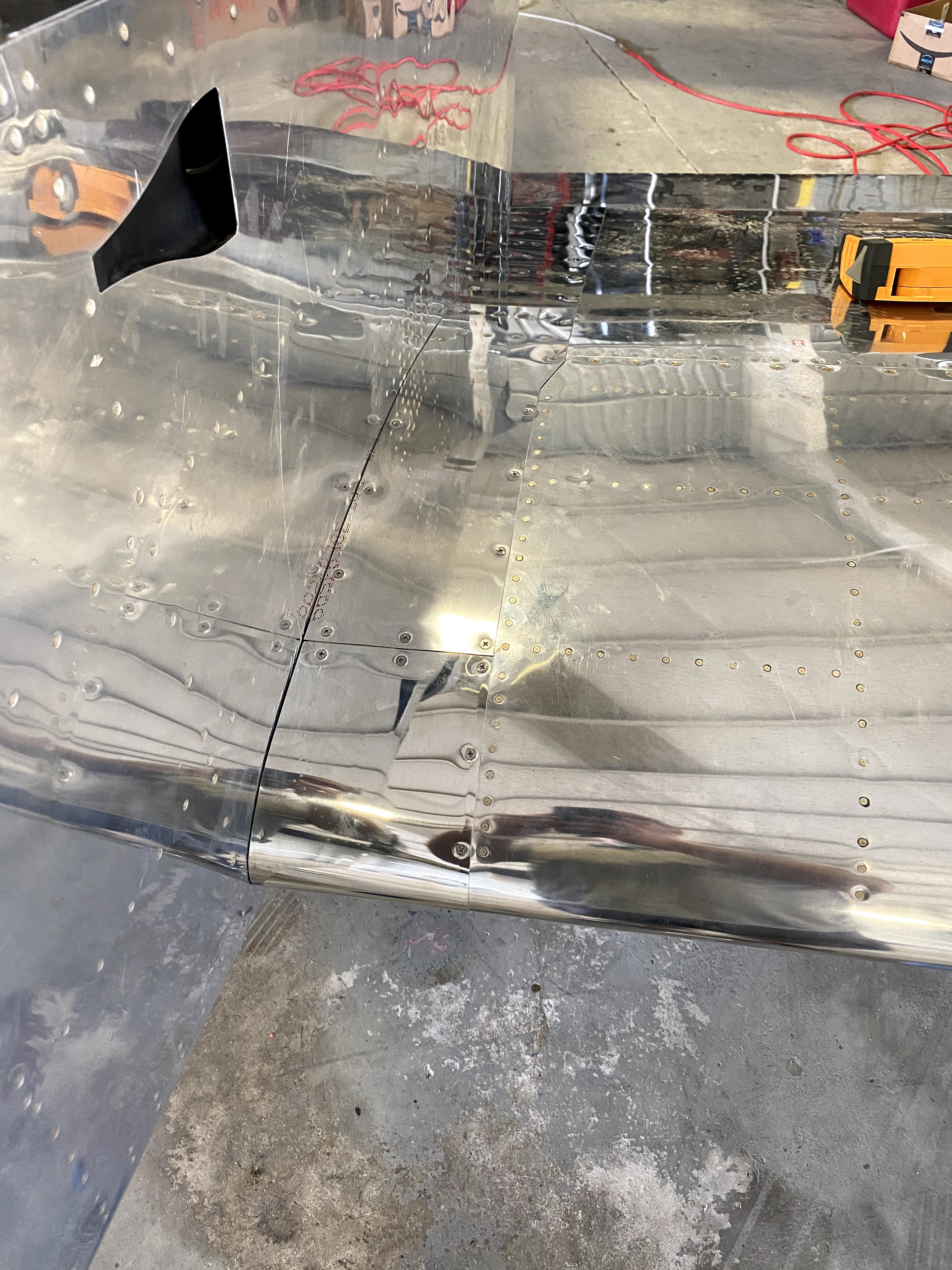

I built and attached the wing root faitings.

Jared came by and helped with the fuel flow test and first engine start. Sorry I neglected to take pictures. Then I spent the next day or so debugging wiring issues and a million other last minute things that I didn’t take pictures of. I did the ELT test and had the avionics shop on the field do the required transponder test. I was ready for inspection on friday but unfortunately the DAR couldn’t make it. He was flying in and the weather was below minimums. So we rescheduled for Sunday.

Then today Vic showed up in his RV-10 and after a thorough inspection turned my project into an airplane with the stroke of a pen.

I spent the rest of the day reinstalling the interior, reinstalling inspection covers, and reattaching all the gear and wheel fairings, as well as the cowling; all of which needed to be removed for the inspection.

And there she is… ready to fly! I just couldn’t be happier with how everything came together. Van’s Aircraft made an exceptionally well engineered kit that made me look good as a builder. `

Weather permitting, I’ll conduct the first-flight and begin phase 1 flight testing next weekend.

| Today’s Time (hours): | 70.00 |

| Finish kit (hours): | 495.0 |

| Total Time (hours): | 1229.0 |

Finished up the canopy, debugged wiring and configured avionics, started on wing attach.

Been working diligently over the last couple of weekends to complete as much as possible before moving to the airport. I’ve secured a spot in a community hangar at KRYY. I’ve also completed my application for airworthiness certificate and scheduled the inspection with Vic Syracuse, our local DAR.

Installed the rear window. Trimmed and fit the aft edge of the canopy and installed the canopy.

Attached the yaw damper bridle cables to the rudder cables.

Brought the wings up to the garage from the basement. Installed the wiring for the GMU 11 and the GTP temperature probe. Created test harnesses to attach the wings to the fuselage in order to test the wiring and avionics.

Spent a fair amount of time debugging wiring and configuring the G3X touch system. I had a couple of CAN bus wiring issues that were pretty easily diagnosed and resolved. I had trouble getting the transponder to power up. This one took a while to figure out but I finally got there. I had mis-pinned the power control line in the high density connector. It was off by one pin. I REALLY wish Garmin had put an LED on the GTX 45R. There was no way to determine wither the box was even powering up or whether there was a data issue. Clearly this box was not designed with installation/maintenance in mind. Inconsiderate engineering!

Fabricated the wing to fuselage fuel lines and fuel vent lines. Made up and installed the aileron and flap push rods.

| Today’s Time (hours): | 32.00 |

| Finish kit (hours): | 425.0 |

| Total Time (hours): | 1159.0 |