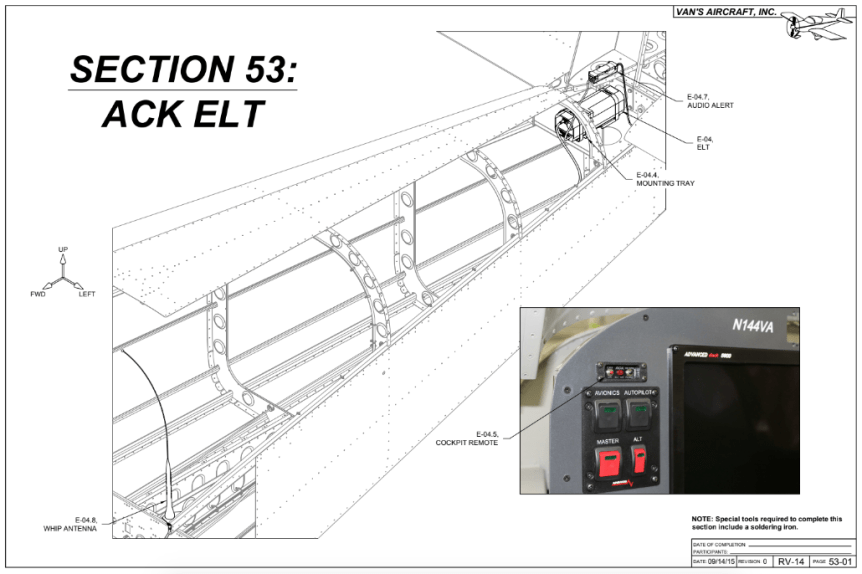

Mocked up the center panel in plexi. Used the Dremel with a cutoff wheel to make the cuts.

Mocked up the pilot-side panel in plexi. I used a fly cutter in the drill press to cut the 3 1/8″ hole for the G5. I centered the ignition/starter switch under the G5 and placed the electronic ignition power switches above the ignition switch. I’ll only need one for now as the engine came with one mag and one P-mag. But I’m making accommodations to switch out the mag for a second p-mag in the future. I grouped the switches along the bottom into logical groupings based upon function. Master and Aux Batt on the left, then boost pump, then lights (landing, nav, strobe), then pitot heat and defroster. I mounted a momentary push button in the center panel right above where the throttle will be. This will be for the AP’s TOGA function.

I laid out the final design on the actual metal blank. I made a couple of alterations. I took the time to better align the G5, Ignition, and P-mag switches. I also moved the row of switches below the GDU downward by 1/4″

Committed the center panel to metal. I used the plexi as a template and drew the cutouts onto the panel. Then I cut it with the Dremel. I fit and fiddled with it using files and many trial fittings. I used files to cut small notches for the GTN’s side guides and for the pall on the bottom of the GTR 200 to make it easier to insert and remove. I’ll likely add a panel light dimmer switch to the center panel at some point. I just haven’t acquired the switch yet.

| Today’s Time (hours): |

6.0 |

| Avionics Time (hours): |

18.0 |

| Total Time (hours): |

693.5 |