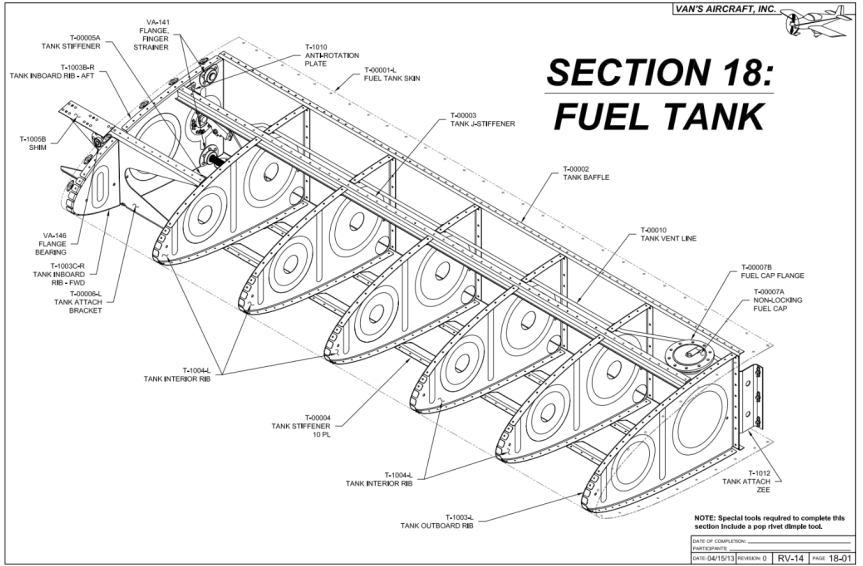

Final drilled the tank attach Z brackets and machine countersunk the nutplate attach holes. I cut the brackets apart on the band saw and cleaned up all the edges on the scotchbright wheel. I riveted the nutplates in place with the squeezer.

I machine countersunk the fuel filler flanges.

I separated the shims with snips and deburred on the scotch bright wheel. I clecoed the the shims to the tank attach brackets and trimmed the ends to be flush with the brackets with snips and cleaned up the edges on the scotchbright wheel. I final drilled all the holes in the shims and dimpled them with the squeezer. I machine countersunk all the holes in the flanges of the attach brackets.

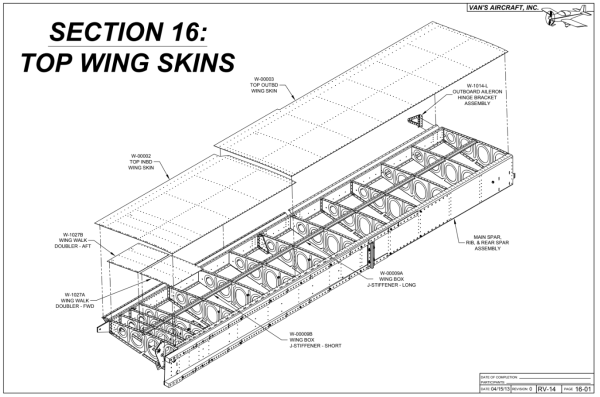

I came up short on J-channel. Not sure whether I didn’t cut the stock I had efficiently when making up the wing stiffeners or if I missed something in inventory. Either way I don’t have anything long enough to make the two 54″ tank stiffeners. I ordered a couple more pieces from Van’s. Should be here next week some time.

| Today’s Time (hours): | 3.0 |

| Wing Time (hours): | 130.0 |

| Total Time (hours): | 341.0 |