Dimpled all the flap parts and scuffed the skins.

Everything is ready for priming and assembly.

| Today’s Time (hours): | 2.0 |

| Wing Time (hours): | 156.0 |

| Total Time (hours): | 367.0 |

Dimpled all the flap parts and scuffed the skins.

Everything is ready for priming and assembly.

| Today’s Time (hours): | 2.0 |

| Wing Time (hours): | 156.0 |

| Total Time (hours): | 367.0 |

Scuffed the top skins, wing walk doublers, and stiffeners and wiped everything down with acetone.

Mixed up a batch of P60G2 and shot everything with primer.

Clecoed the left skins and doublers to the left wing substructure.

Remy helped my rivet the skins to the ribs and spars. Prefers bucking and I prefer shooting so it all works out.

Finished riveting the spars and ribs and clecoed the J stiffeners in place. I’m really pleased with the result so far. The riveting went really smoothly. No dents!

| Today’s Time (hours): | 5.0 |

| Wing Time (hours): | 80.5 |

| Total Time (hours): | 291.5 |

Peeled the vinyl from all the parts. Did the minor cutting and fabrication called out in the plans. Cleaned up and deburred all the edges with file, deburring tool, scotch brite wheel, and sandpaper. Scuffed everything with a scotch brite pad.

Assembled and final drilled the aileron hinges. The inboard hinges are from the service bulletin. I’m surprised they haven’t updated the plans yet. Had to follow the SB instructions.

Clamped the spar doublers to the spars and match drilled them.

Drilled out the aileron pushrod hole in the inboard doublers and cleaned them up with the Dremel.

Clecoed the right rear spar together with the wing assembly.

| Today’s Time (hours): | 4.5 |

| Wing Time (hours): | 59.0 |

| Total Time (hours): | 270.0 |

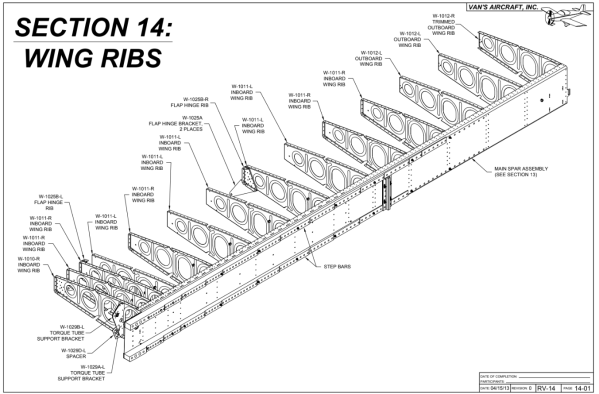

Netflix and scuff! Sophie deburred and scuffed all the ribs while I was traveling this week. Awesome job!

I fluted and straightened all the ribs.

I assembled and final drilled #30 the torque tube bracket assemblies.

I clecoed the torque tube bracket assemblies to the inboard-most ribs and final drilled them to the rib webs.

I clecoed the flap brackets and flap bracket ribs to the inboard and outboard wing ribs and natch drilled all the #30 holes.

| Today’s Time (hours): | 10.0 |

| Wing Time (hours): | 34.5 |

| Total Time (hours): | 245.5 |

Cut and deburred all the rib parts.

Took the blue plastic off al of the ribs.

Final drilled #40 the top and bottom flanges of all the ribs.

Sophie helping out with scuffing and deburring.

| Today’s Time (hours): | 3.0 |

| Wing Time (hours): | 24.5 |

| Total Time (hours): | 235.5 |

Match drilled the J channel to the spar.

Machine countersunk the nutplate attach holes.

Riveted in the nutplates

Countersunk the screw holes.

Machine countersunk all the skin attach holes.

Riveted in the nutplates at the tip end of the spar.

Riveted the doubler to the spar and installed the tank attach nutplates.

Final drilled, deburred, scuffed and primed the aileron bell crank brackets

Installed and torqued the aileron bell crank brackets.

Right spar done!

| Today’s Time (hours): | 4.5 |

| Wing Time (hours): | 21.5 |

| Total Time (hours): | 232.5 |

I deburred, scuffed and primed all of the remaining empennage parts including the top skin and the upper side skins. I’ve just about run out of parts. Once I get my static line and nut plates from Van’s, I’ll be able to finish riveting everything.

| Today’s Time (hours): | 3.0 |

| Empennage Time (hours): | 173.0 |

| Total Time (hours): | 173.0 |

I peeled the blue vinyl from the j channel that’s formed into the edges of the bottom skin so that I could scuff and prime those along with the inside of the skin.

First batch of four ready to shoot.

Second batch was the rest of the bulkheads and bell crank ribs (not pictured) and the third batch included the longerons and stiffeners. The last batch was the bottom skin.

Et viola!

Tomorrow I’ll begin assembling the tail cone. Once I get the substructure assembled and riveted to the bottom skin, I’ll have one more big scuff and prime session for the skins and the few remaining substructure components.

| Today’s Time (hours): | 3.0 |

| Empennage Time (hours): | 147.0 |

| Total Time (hours): | 147.0 |

I cut the aft tail skin with the snips. Cutting .040 aluminum with snips is a workout. I thought of using the band saw but it’s an awkward part to cut straight with the saw. I trusted my skills with the snips more than steadiness of my hand at the band saw. Good result but my forearm was pretty sore afterward.

Cleaned it up with file and sand paper.

My paint cutter arbor arrived from Aircraft Spruce. So I was able to cut the remaining countersinks in the rudder stops without the cage.

I was skeptical that I’d be able to hit the right depth free hand but it worked out fine.

I also heard back from Van’s support on the holes that I thought shouldn’t be dimpled and in fact they shouldn’t have. So I hammered them flat. This was definitely an error in the plans. Now my tie down bracket sits flush.

And finished up with a marathon scuffing session.

I’ve got to be honest. Scuffing parts is my least favorite part of the process. It’s dusty messy work.

That was a lot of parts to scuff but I’m glad I fought through and got them done. This is most of the parts for the tail cone. Once these are primed, I’ll only have the skins and a few small parts left to scuff and prime in order to complete the empennage. Big priming session tomorrow. Then I can start assembling. 🙂

| Today’s Time (hours): | 3.0 |

| Empennage Time (hours): | 144.0 |

| Total Time (hours): | 144.0 |