Deburred all the edges of all the things. The doublers for the landing light lenses looked like they were crafted by Van’s with a chainsaw. You can see the before and after shot below. I used sandpaper to work the flanges around the nose of the ribs so that the skins don’t telegraph any faceting.

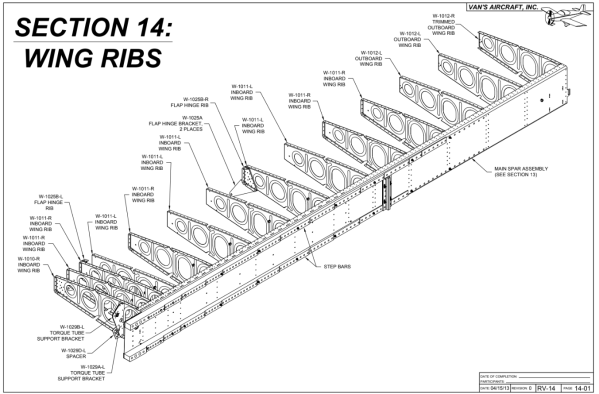

Trimmed the four ribs called out in the plans so that they will fit around the spar braces. Finished with files and sandpaper.

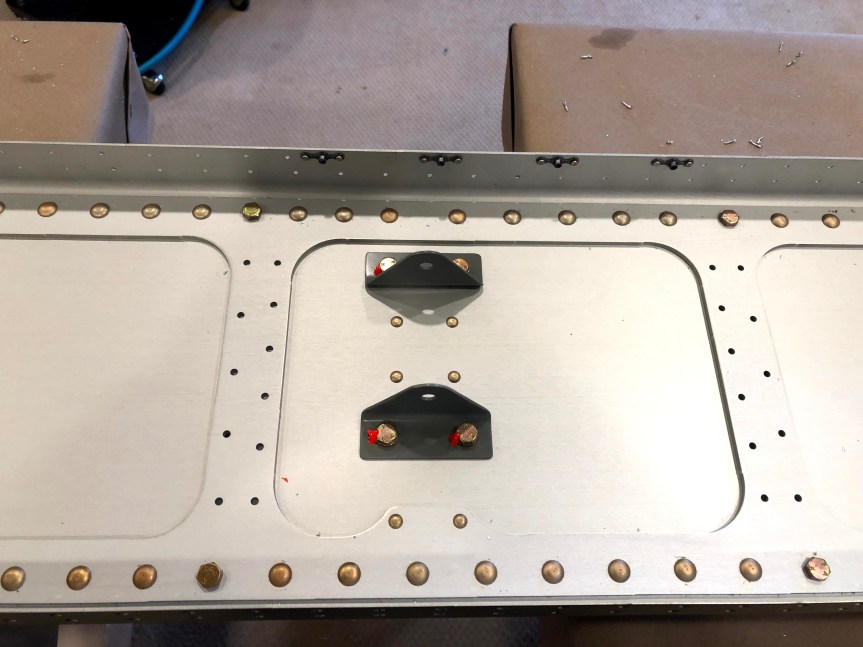

Flattened, straightened and fluted all the ribs. Then final drilled and deburred all the holes.

Dimpled all the holes with the squeezer.

Cut the J-channel stiffeners to length and drilled the first inboard hole in each.

Final drilled #19 the screw holes in the splice strips. Carefully deburred the holes and dimpled for #8 screws. Dimpled all the #40 holes as well.

In other news, I received the order confirmation for the engine I ordered at Sun ‘n Fun. The ship date from Lycoming is October 11.

| Today’s Time (hours): | 5.0 |

| Wing Time (hours): | 94.0 |

| Total Time (hours): | 305.0 |